Heat exchangers are systems that are used for power generation using heat transfer between an energy source and a fluid. While technology has been around for a century or two, the design and use of these systems have improved significantly. Heat exchange systems are used in various industries and vary immensely in design. Heat exchangers are used in industries such as oil refineries, food, and chemical processing, and many others. The technology is also found in consumer products such as refrigerators, automobiles, etc. Heat exchange can be used for both heating and cooling processes.

Apart from lowering industrial energy costs, heat exchangers have many other benefits when it comes to industrial energy. Here are just a few of the reasons why this technology has become so popular over the years.

Lower Costs

Energy is a critical component of any industrial process, and many companies struggle to keep energy-generation costs to ensure that their operations are profitable. Unfortunately, this is not always possible. Heat exchangers are among the few energy generation technologies that are quite cost-effective. This is not just in the running of the systems but also in maintenance. This is partly because the basic technology of the systems is quite straightforward and simple. They also lack many additional parts which in turn eliminate potential areas of failure.

Reduced Spatial Footprint

When it comes to industrial plants, space comes at a premium. For this reason, any system that utilizes little space is always welcome, as it means that plants can operate with minimal space, allowing them to do more. Heat exchange systems are great because they require relatively less space than most other heat generation technologies. For this reason, they are quite popular in industrial plants.

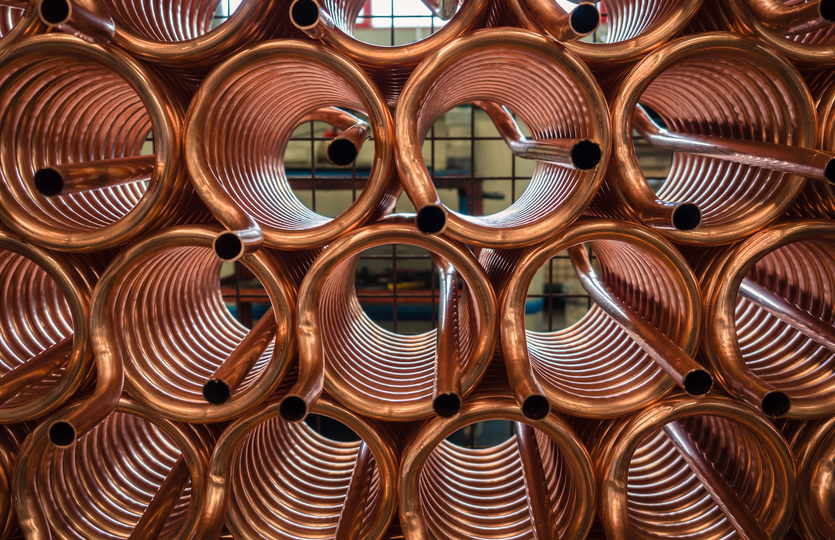

Adaptability

Heat exchange systems can be adapted to work in very many different designs, allowing them to be used in different industrial designs. While the basic technology is the same, heat exchangers have been redesigned over the years to fit into the infrastructural design of many different plants. This allows different factories to customize their heat exchangers and ensure that they are getting optimum returns from their systems.

Lower Carbon Footprint

Apart from being cost-efficient, heat exchange systems are great in that they are also relatively eco-friendly. There are minimal carbon emissions in the process, as well as minimal waste. For example, the fluid that is used in heat exchange is often recycled, which in turn reduces waste products from the system. In an era where companies are looking for ways to generate energy efficiently without impacting the environment, heat exchangers are a welcome addition to many industrial processes. This feature will become even more critical as global warming becomes increasingly important. With many governments looking to reduce carbon emissions by industrial plants through higher taxes, having an energy-efficient system can translate to real cost savings over the years.

Easy Installation

Given the fact that heat exchange technology has been around for a while, it is a process that is well understood, making it a lot more dependable than most other energy generation systems. It also means that installation is relatively easy compared to other energy-generation systems.